In the process of UV drying , ultraviolet light interacts with chemical specifically designed to dry ink and paint more quickly and cheaply than conventional drying systems. UV technology has been developed over 30 years ago especially for the printing industry and the wood industry, but today is also used in various areas such as the automotive industry.

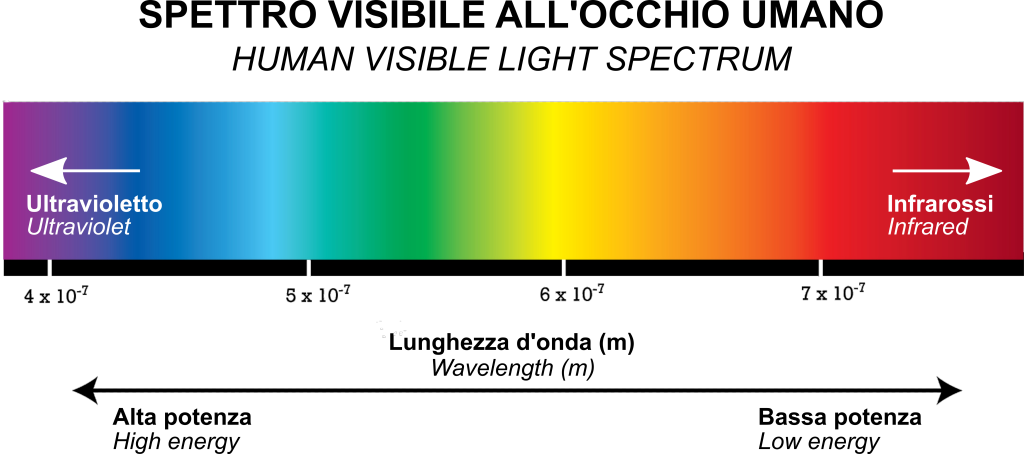

Ultraviolet radiation (so-called UV or ultraviolet rays or ultraviolet light) is an electromagnetic radiation, belonging to the electromagnetic spectrum, which emits a shorter wavelength than that of visible light but longer than X-rays. The name means “beyond violet” (from Latin ultra, “beyond”) because the spectrum consists of electromagnetic waves with higher frequencies than those that humans identify as the colour violet, being the one with the shortest wavelength.

Ultraviolet light can be divided into two ranges: near UV spectral range (380-200 nm) and far-UV spectral range (200-10 nm). When considering the effect of UV radiation on human health, the range of UV wavelengths is typically divided UV-A (400-315 nm), UV-B (315-280 nm) and UV-C (280-100 nm). The Sun emits ultraviolet light at all three bands UV-A, UV-B and UV-C but, due to the absorption by the first Ozone layer of the atmosphere, about 99% of ultraviolet rays that reach the earth’s surface is UV-A. Almost 100% of the UV-C rays and 95% of UV-B rays is filtered by Earth’s atmosphere.

For further information about traditional UV lamps visit the related product page:

|

UV lamps |

The advantages of using inks/UV based paints are numerous, among which we can highlight:

The UV drying process requires first of all a light source that directs its light on a painted surface; the layer of color (paint or ink that is) is composed of a product called photo-initiator, which has the fundamental task of absorbing UV energy from the light and trigger a chemical reaction, that within a few fractions of a second, converts the layer from liquid to solid. The composition of this particular product is made up of monomers and oligomers: the first are low molecular weight materials and have the task of creating physical links due to the curing of the paint (or ink) during exposure to UV rays; the monomers also act as diluent in some products which are generally used to correct the viscosity of the product which lies on the surface, so they are also called reactive diluents. In contrast, oligomers tend to have a very high molecular weight, and are generally responsible for determining the degree of finish of the painted surface, such as flexibility, subtlety, etc.

Environmental sustainability. Energy efficiency. Ecology. SPM has the ideas and technologies to transform words into deeds. Here’s how the SPM products contribute to reduce environmental impact:

For further information about UV QBe electronic power supply visit the related page:

|

UV QBe electronic power supply |

Below are shown schematically the main benefits, grouped into three categories,resulting from the use of a QBe power supply series. For more information please contact us using the contact details in the relevant section.

UV Radiation

There are no “dark periods”: higher yield of the lamp at the same power supplied, compared to a conventional power supply or greater saving due to less frequent lamp changes.

UV drying system:

Energy saving: